Tel:+1(832)623-5198

Add: 27607 Balcones Heights blvd Fulshear,TX 774441.

China office:

Tel: +86 571 89804433

Fax: +86 571 81603593

Email: Market@cqaltd.com

Web: www.cqaltd.com

www.cqachina.com

Add: Room 901, Tianheng building,No.1509 Binsheng Road, Binjiang District, Hangzhou city, Zhejiang Province, China

Positive Material Identification (PMI)

The Objective

While engineers push the boundaries of material capacities to their limits in the design, traceability of proper material becomes ever more important. In addition to compatibility issues, several other reasons can exist for material specification including design, corrosion resistance, and compliance to codes and standards such as ASME Boiler and Pressure Vessel Code.

Quality procedures are put in place to document materials as they are received and as they move through the production process, but what happened to those raw materials before they arrived at the receiving dock? Each time raw material changes hands - from the mill to service centers, from processing plants (e.g., pipe, tube and fittings) to subcontractors ĘC the opportunity for error increases, resulting in questionable material quality.

The Solution

With Positive Material Identification (PMI) the alloy composition, and thus, the identity of materials can be determined. If a material certificate is missing or/and you need to be certain about the type of material used, PMI as an NDT method is the best solution. Positive Material Identification is particularly used for high quality metals like stainless steel and high alloy metals.

There are two methods of Positive Material Identification:

1:The XRF-principleX-ray

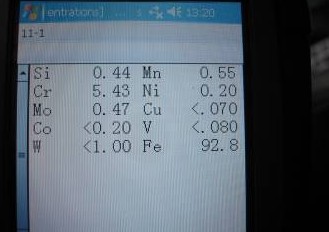

fluorescence is one of the methods for PMI. The equipment contains radioactive sources or a low voltage x-ray generator, which sends out radiation. The exposed material then sends temporarily element specific radiation back, generating energy. As every element has its own atomic structure, this reflection will generate a different energy level for every element.

This energy is measured and detected, thus identifying the alloy elements. The disengaged radiation is very low and extra safety means are not necessary. The important advantage of the XRF-method is that it in service can be executed without damaging the material. Directly after the inspection, you will receive the results.

2:Spark emission spectrography

Spectrography is based on optical emission. The equipment consists of a probe which releases a spark that is used to vaporize the material being analyzed. The atoms and ions in this vapor produce a spectrum which can be optically measured and then recalculated to determine the components of the material.

|

|

|