Tel:+1(832)623-5198

Add: 27607 Balcones Heights blvd Fulshear,TX 774441.

China office:

Tel: +86 571 89804433

Fax: +86 571 81603593

Email: Market@cqaltd.com

Web: www.cqaltd.com

www.cqachina.com

Add: Room 901, Tianheng building,No.1509 Binsheng Road, Binjiang District, Hangzhou city, Zhejiang Province, China

Sampling Method and Quality Standards

Method of acceptance sampling

This proven method is widely used to decide whether or not to accept or reject a production lot without checking every single items of the lot. Performed on randomly-selected sample items, once the production lot has been completed and packed, this standard is recognized by every industrial company.

Acceptance sampling is not an alternative to process improvement. Instead it should complement improvement efforts by providing incentives. It also serves as a temporary measure for ensuring quality until successful improvements are made.

Focus on Acceptable Quality Levels

CQA quality inspectors use the ISO 2859 tables (also known as AQL tables) to measure acceptable levels of quality. These tables are a US standard with equivalents in all national and international standardization organizations (ANSI/ASQC Z1.4, ISO 2859, NFX06-022, BS 6001, DIN 40080).

How do I determine the right sample size and acceptance number?

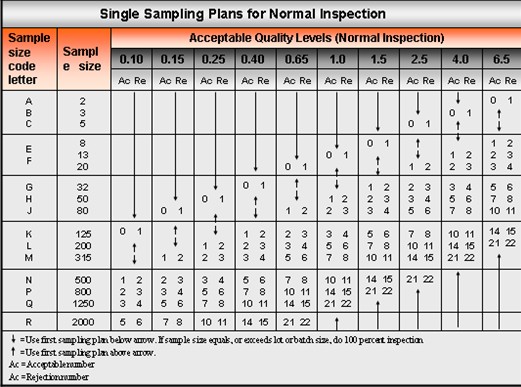

For a hypothetical inspection of a 2,000-unit lot, with an Acceptable Quality Level of II, Table B indicates that the sampling size should be 125 units. For an AQL of 2.5, the corresponding acceptance number is 7. If the number of defective units is higher than 7, the lot has to be rejected.

What should I do with defective or discarded lots?

Defective items found as part of 100% inspection can be discarded, repaired or replaced. You may also option to sell the discarded lot at a discount.

Sampling standard

CQA¡¯s inspectors use the ISO 2859/ANSI/ASQC Z1.4/MIL-STD-105E/BS 6001/DIN 40080/NF X 06-022 tables for sampling. The tables are recognized by every industrial company. This American standard has equivalents in all national and international standardization organizations. This standard is a proven method to accept or reject a production lot by inspecting a randomly selected number of products.

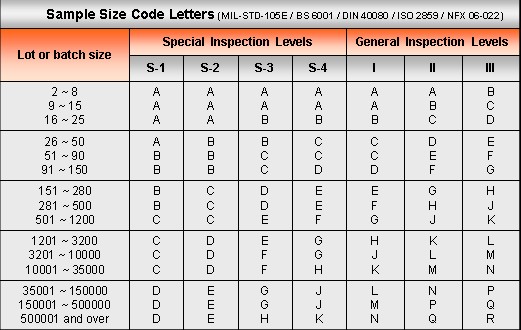

TABLE A

TABLE B

Acceptance Sampling

Acceptance Sampling is used to decide whether to accept or reject a production lot. It is performed once the production lot has been completed and packed. Basic procedures for Acceptance Sampling:

- select a sample from a production lot,

- inspect the units in the sample,

- use the result to decide whether or not to accept or reject the lot.

AQL (Acceptable Quality Levels)

As a quality control company, CQA uses the Acceptable Quality Level (AQL) to establish a maximum allowable error rate or variation from the standard. Acceptance testing will cease immediately if the failure rate of the product being tested exceeds the minimum Acceptable Quality Level.

Batch/Lot

A batch or lot is a collection of products ¨C all identical in size, type, conditions and time of production ¨C from which a sample will be taken to decide whether or not it conforms to the acceptance inspection.

Sample size code letter

The sample size code letter is the link between AQL tables A and B.

Sampling Level

This reference determines the relation between the size of the lot and the size of the sample inspected. For a given lot size, increasing the Quality Level means increasing the Sample Size. This improves accuracy but also increases the time needed to complete the inspection. The Quality Level may be chosen between I, II, or III. CQA¡¯s default Quality Level is II.

Special Inspection Level

The Special Inspection Level is used instead of the general inspection level when the production has to be operationally inspected. The special inspection level can range from S1, S2, S3 or S4.

Sampling size

The sampling size is the total number of units to be inspected.

Rejection number

The Rejection Number is equal to the acceptance number + 1 and represents the maximum allowable defective units. If the total number of sampled products presenting this type of defect is equal or superior to the rejection number, the production has failed.

Defect classification

Defects detected during inspections are generally classified in 3 categories:

- Critical Defect

A defect which experience and judgment indicates is likely to result in hazardous and/or injurious situation to the user, or makes the product subject to legal seizure.

You can provide your own list of critical defects to be inspected.

CQA¡¯s default Critical Defect AQL is 0.

- Major Defect

A defect excluding Critical Defects is likely to result in failure, or reduced the usability of the unit for its intended purpose, or which affects the salability of the products.

You can provide your own list of Major Defects to be inspected.

CQA¡¯s default Major Defect AQL is 1.5.

- Minor Defect

A defect that is not likely to reduce the usability of the product unit for its intended purpose, or is a departure from established standards having little bearing on the effective use or operation of the unit. A Minor Defect is nevertheless a workmanship defect beyond the defined quality standard.

You can provide your own list of Minor Defects to be inspected.

CQA¡¯s default Minor Defect AQL is 4.0

ISO

ISO is the International Organization for Standardization founded in 1946 to promote the development of international standards and related activities, including conformity assessment, to facilitate the exchange of goods and services worldwide. ISO is composed of member bodies from over 90 countries and covers all areas except those related to electrical and electronic engineering, which are covered by the International Electro-technical Commission (IEC). The results of ISO's technical work are published as International Standards or Guides.